The Amp Hour Electronics Podcast

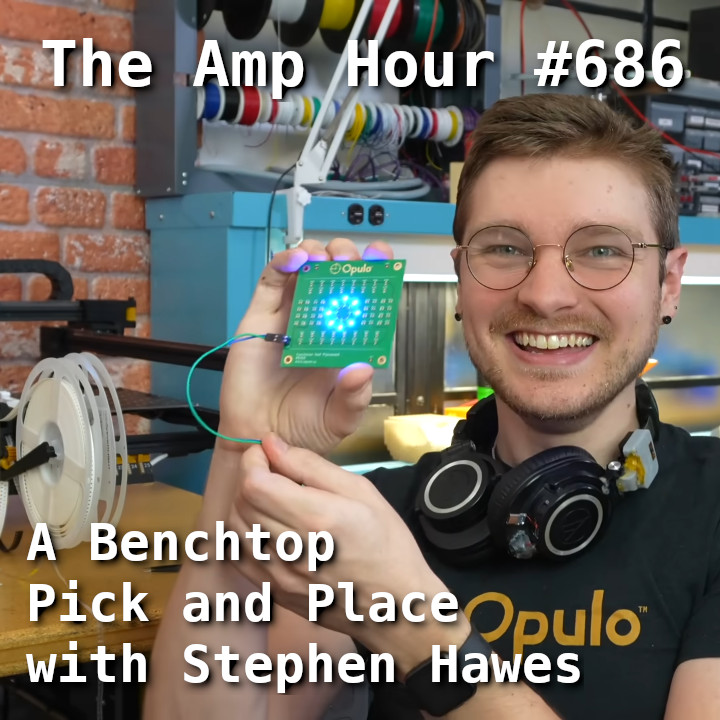

The Amp Hour Electronics Podcast #686 – A Benchtop Pick and Place with Stephen Hawes

16 snips

Jan 21, 2025 Stephen Hawes, founder of Opulo and creator of the Lumen pick and place machine, shares insights from his journey in open-source hardware. He discusses the challenges faced in developing the Lumen, its unique dual-nozzle system, and how it compares to other assembly methods. Topics include the calibration process of machines using OpenPNP, innovative uses of vacuum sensors, and the importance of community engagement in open-source projects. Stephen also reflects on the evolution of PCB manufacturing and encourages exploring new DIY innovations.

AI Snips

Chapters

Transcript

Episode notes

Kickstarter Bow Ties

- In 2019, Stephen Hawes launched a Kickstarter for light-up bow ties.

- Hand-assembling 100 units proved difficult, and outsourcing was too expensive, inspiring him to build a pick-and-place machine.

Bootstrapping Opulo

- Stephen Hawes quit his job at Formlabs and moved to Pittsburgh to pursue his pick-and-place project full-time.

- He bootstrapped the project with Patreon support and later received an investment from Joel Spolsky.

Lumen PNP Target Audience

- The Lumen PNP machine targets low to medium volume PCB assembly, ideal for in-house prototyping or small R&D teams.

- It helps companies avoid long turnaround times from external assembly services.